Add Your Heading Text Here

SPECIFICATION

The start of every new project consists of ensuring everybody involved has a complete understanding of the final requirements and the market demands. So the first step is to develop a robust, widely accepted design specification. This can be straightforward, but sometimes requires tradeoffs in terms of function, dimension or, often, cost..

In order to ensure the final feasibility, concrete proposals for the technical implementation must already be available when creating the concept. With the intention to ensure that the best solution defines the product, competing approaches may be agreed up to a leading prototype status.The final aspect must be producibility. A great product that meets the requirements in terms of function, dimensions and price, but is extremely complicated to manufacture, is beyond every financial scope.

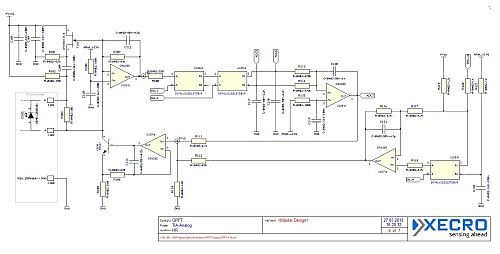

CIRCUIT DESIGN

Our engineering team uses Pulsonix to undertake electronic circuit design and schematic capture. Schematics are carefully reviewed by the project owner against the design specification and by the assigned software engineer against special pinout requirements before proceeding to PCB layout.

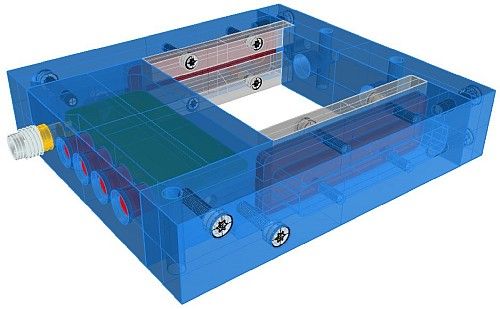

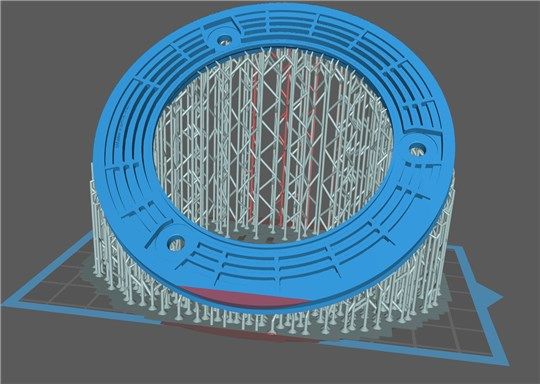

MECHANICAL DESIGN

Decades of experience in product design with Rhinoceros 3D, allow us to construct functional and visually appealing solutions. Whenever required, we produce prototypes by CNC milling or using 4K-3D-SLA printer. These prototypes are extremely detailed and ensure that everything finally fits together. A nice side effect is, that marketing, engineering and customers can experience the product hands-on at a very early stage.

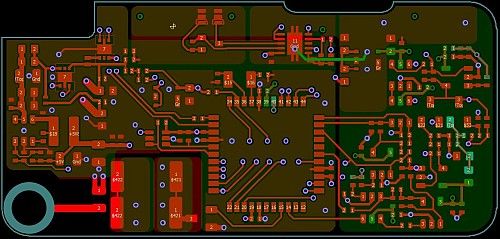

CIRCUIT DESIGN

In parallel with mechanical design, our engineers apply ages of experience in producing optimally designed PCB layout files using Pulsonix. A large library of well-tried, optimized footprints of components we daily use, ensures that both, the placement of components as well as the soldering results are reliable.

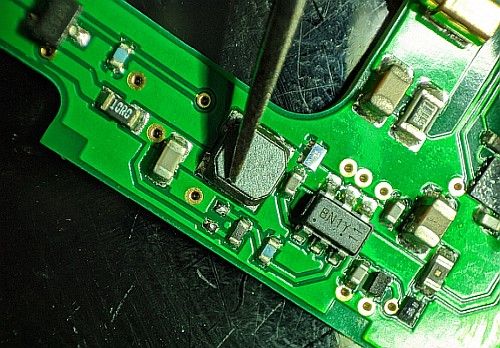

PCB ASSEMBLY

Since setting up the pick & place machine takes longer than an experienced technician needs to fit a handful of prototypes, this process usually takes place by hand. At the same time, wishes of the developer can be taken into account and versions with different component values can be produced.

The manual assembly process requires experience in handling the smallest parts. One of our frequently used microcontrollers, for example, has an area of 3×3 mm, with 20 (!) circumferential electrical connections. The solder paste is applied with a stencil and the same paste printer that will also be used in the later series. In this way, component placement, paste printing and the soldering process are already part of the hand-made prototype.

PROTOTYPING

With leading-edge on-site PCB assembly equipment, 3D printing, laser cutting and CNC milling, we can easily produce fast turn-around prototypes for test and verification throughout the design process.

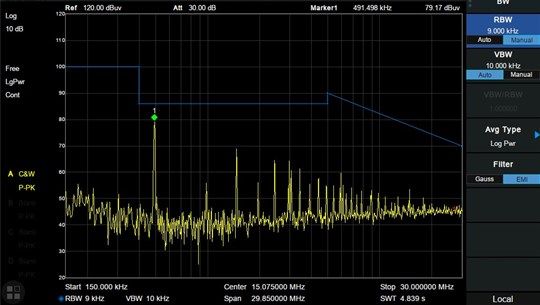

APPROVALS

With years of experience in electronic design and on-site facilities to undertake pre-compliance EMC testing, the team at XECRO is ideally placed to ensure the approval process for industrial electronic products.

COMPLIANCE

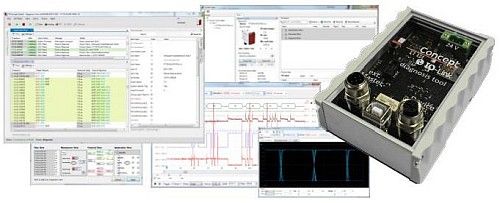

The IO-Link Consortium requires that every IO-Link device has a Manufacturer’s Declaration stating compliance with the specifications. Numerous tests defined in the Test Specification are necessary to accomplish this.

XECRO meets these complex requirements by using IO-Link Device test equipment from TEConcept.

APPROVALS

XECRO is using a BINDER® environmental test chamber to test products under dynamic conditions. The standard rapid alternation speeds of aproximately 5 K/min, with a total range of -40… +180 ° | 356 °F, make standard-compliant testing possible.

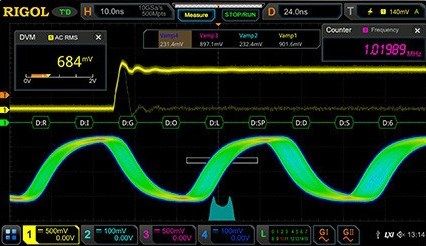

VERIFICATION

Although verification is integral to each stage of the design process, we always undertake a complete product verification against the original specification before a product is released for production.

PREPARATION OF MANUFACTURE

Our considerable experience with manufacturing processes is critical to ensure a successful and timely product development process as well as the results of design projects, the most cost-effective production and consistently high quality.

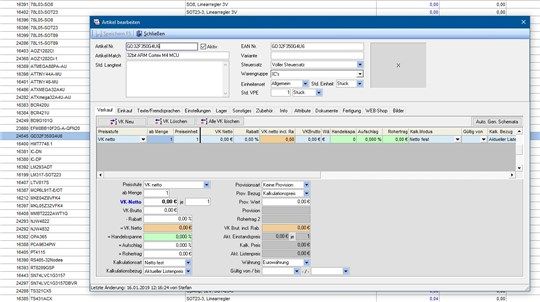

Our ERP software includes a production planning module. It reads parts lists directly from Pulsonix and directly interacts with wall mounted production status displays. Production lots, supply chains, parts lists and minimum stocks for components are managed centrally in our ERP system.

PRODUCTION

Sustained success is driven by customer satisfaction which depends on the quality of our products and services.That’s why XECRO was opting for ISO9001:2015 vertification by DQS for the follwing processes:

- Product Development

- Production of Industrial Electronics

- Sales and After-Sales Services